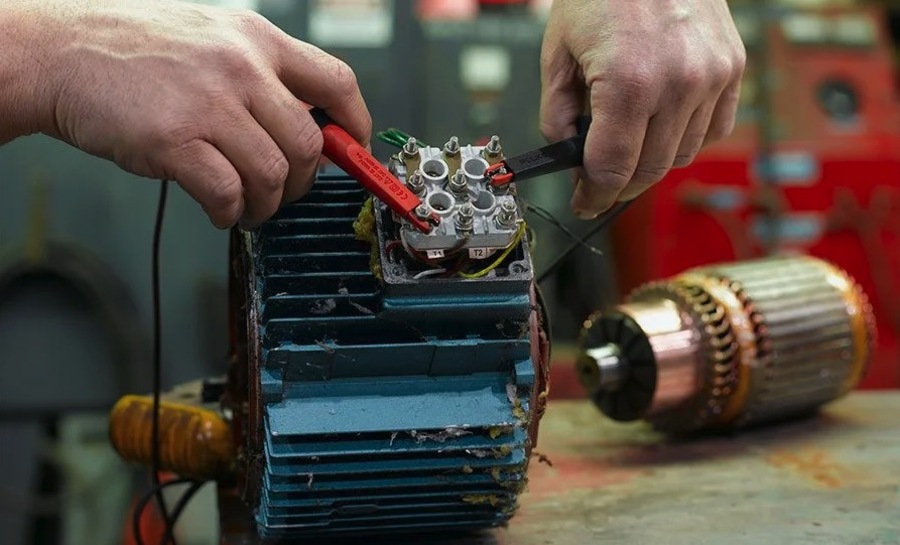

Electric motors are an integral part of modern life, powering everything from household appliances to industrial equipment. These devices convert electrical energy into mechanical energy through electromagnetic interactions. In this article we will consider in detail the description and principle of operation of electric motors, their classification, history of creation and significant role in our daily life. For those who need to repair electric motors, please contact Al Ghaima Engineering Company LLC , this company has vast experience related to the maintenance and restoration of these important machines.

Detailed Description and Principle of Operation

An electric motor is a device that converts electrical energy into mechanical energy using electromagnetic principles. It typically consists of several key components:

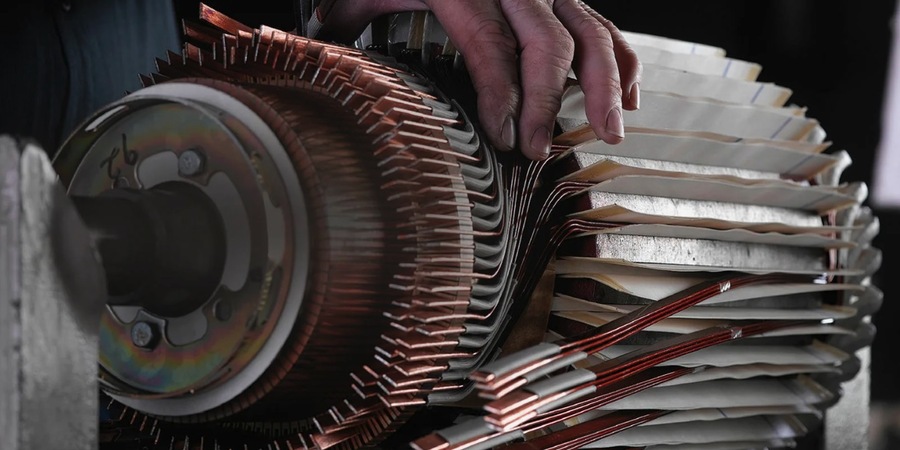

Stator: The stationary part of the motor, usually comprising coils of wire that create a magnetic field when current flows through them. The stator provides the necessary magnetic field to interact with the rotor.

Rotor: The rotating part that is placed inside the stator. It interacts with the magnetic field to produce motion. The rotor can be either wound or squirrel-cage type, depending on the motor design.

Commutator and Brushes (in some motors): These components help in switching the direction of current flow, ensuring continuous rotation. Commutators and brushes are primarily found in DC motors and some types of universal motors.

Principle of Operation

The basic principle behind an electric motor is based on the interaction between a magnetic field and electric current, resulting in a force that moves the rotor. This principle, known as Lorentz force, can be summarized as follows:

- When an electric current passes through the coils in the stator, it generates a magnetic field.

- The rotor, placed within this magnetic field, experiences a force due to the interaction of the magnetic field and the current flowing through it.

- This force causes the rotor to rotate, converting electrical energy into mechanical energy. The rotation of the rotor then drives a mechanical load connected to it, such as a fan blade, pump, or conveyor belt.

Classification of Electric Motors

Electric motors are classified based on the type of current they use and their construction. Here are the main categories:

DC Motors

DC motors run on direct current (DC) electricity. They are known for their simplicity, ease of control, and wide range of applications. Key types include:

– Brushless DC Motors: These motors do not use brushes for commutation, leading to higher efficiency and less maintenance. They are commonly used in computer cooling fans, electric vehicles, and drones.

– Brushed DC Motors: These motors use brushes and a commutator to switch the direction of current, making them simpler but requiring more maintenance. They are often found in household appliances, toys, and automotive applications.

Pulsating Current Motors

Pulsating current motors operate on a form of DC that is not constant but pulsates. These motors are typically used in applications where a simple and cost-effective solution is required. They are often found in low-power applications such as small household appliances and battery-operated devices.

AC Motors

AC motors run on alternating current (AC) electricity. They are widely used in industrial and household applications due to their robustness and efficiency. Key types include:

– Synchronous Motors: These motors operate at a constant speed, synchronized with the frequency of the AC power supply. They are used in applications requiring precise speed control, such as clocks, record players, and conveyor systems.

– Induction Motors (Asynchronous Motors): These are the most common type of AC motor, where the rotor is induced by the magnetic field of the stator. They are known for their durability and simplicity and are widely used in industrial machinery, pumps, fans, and compressors.

Universal Commutator Motors

Universal commutator motors can operate on both AC and DC power. They are known for their high speed and torque, making them ideal for portable power tools and household appliances. Examples include vacuum cleaners, blenders, and drills.

History of the Electric Motor

The development of the electric motor is a fascinating journey of scientific discovery and engineering innovation:

Early Discoveries and Inventions

– Michael Faraday (1821): Faraday demonstrated the principle of converting electrical energy into mechanical energy using electromagnetic fields. His experiments laid the foundation for the development of electric motors. Faraday’s simple yet groundbreaking experiments involved a magnetic field and a wire carrying an electric current, which resulted in rotational motion.

– Barlow’s Wheel: An early device that demonstrated the principle of a homopolar motor, an important step in the evolution of electric motors. Barlow’s Wheel was a significant development, showing that a continuous rotational motion could be achieved using a direct current.

Key Milestones

– B.S. Jacobi (1834): The Russian-Prussian scientist created the world’s first practical electric motor with a rotating armature. This motor marked the beginning of the practical application of electric motors. Jacobi’s motor was powerful enough to drive a small boat carrying several passengers across the River Neva in St. Petersburg.

– Galileo Ferraris (1885): Ferraris invented the first two-phase asynchronous motor, paving the way for the development of more efficient AC motors. His work on rotating magnetic fields was crucial for the advancement of AC motor technology.

– Mikhail Dolivo-Dobrovolsky: A pioneer in electrical engineering, Dolivo-Dobrovolsky created the first three-phase AC motor, which became the standard for modern AC motors due to its efficiency and reliability. His three-phase system is still used in today’s power distribution networks and industrial applications.

The Ubiquity and Importance of Electric Motors

Electric motors are ubiquitous in modern life. They range from tiny motors in household appliances, like laptops and kitchen gadgets, to powerful motors that drive industrial machinery and elevators. Their versatility and efficiency make them indispensable across various industries.

In the UAE, where advanced technology and industrial growth are paramount, maintaining the functionality of electric motors is crucial. Companies like the Al Ghaima Engineering Company LLC specialize in the repair and maintenance of electrical equipment, ensuring that the vital components of modern infrastructure continue to operate smoothly. The ability to quickly and efficiently repair electric motors is essential for minimizing downtime and maintaining productivity in various sectors.

Conclusion

Electric motors are a cornerstone of modern technology, driving countless devices and systems that we rely on every day. From their humble beginnings in the 19th century to the sophisticated machines of today, electric motors have continually evolved to meet the demands of an ever-changing world. Whether in small household appliances or large industrial machines, their importance cannot be overstated. For those in need of expert repair and maintenance services, companies like the Al Ghaima Engineering Company LLC provide essential support, ensuring the longevity and efficiency of these crucial devices. With advancements in technology, the future of electric motors looks promising, with continued improvements in efficiency, performance, and sustainability.